ASTM B387 Molybdenum Heat Shields For High Temp Furnace

Molybdenum Heat Shields can be used in air and various gas

environments. The working temperature of the MoSi2 heating

element is 1300C to 1800C. It has the characteristics of

high-temperature resistance, oxidation resistance, corrosion

resistance, heating fast, long service life, high-temperature low

distortion, easy installation and maintenance, excellent chemical

stability

Introduction

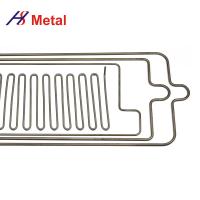

The molybdenum heater and Tungsten heater are used as heat

insulation components, which play an essential role in heat

insulation and reflection in the sapphire growth furnace, tungsten,

and molybdenum materials are the best choice for the

high-temperature furnace heating elements as their High-density,

high-temperature strength, accurate measurement, smooth surface,

convenient assembly, and reasonable design of heat components are

of great significance for improving the crystal pulling

performance.

We suggest that the operating temperature of the heater is not more

than 2,000℃

and the operating temperature of the Tungsten heating chamber is

not more than 2,800℃

Customized Furnace Heat Chamber Parts Molybdenum Heater Parameters

| Chamber size( W*H*Dmm) |

| 100*100*100mm |

| 120*120*130mm |

| 150*150*150mm |

| 200*200*200mm |

| 200*200*300mm |

| 250*250*300mm |

| 300*300*400mm |

| 600*600*600mm |

| We accept customized Molybdenum heaters and other parts according

to your specific requirements or drawings. |

| Atomic number | 42 |

| CAS number | 7439-98-7 |

| Atomic mass | 95.94 [g/mol] |

| Melting point | 2620 °C |

| Boiling point | 4639 °C |

| Density at 20 °C | 10.22 [g/cm³] |

| Crystal structure | Body-centered cubic |

| Coefficient of linear thermal expansion at 20 °C | 5.2 × 10-6 [m/(mK)] |

| Thermal conductivity at 20 °C | 142 [W/(mK)] |

| Specific heat at 20 °C | 0.25 [J/(gK)] |

| Electrical conductivity at 20 °C | 17.9 × 106 [S/m] |

| Specific electrical resistance at 20 °C | 0.056 [(Ωmm2)/m] |

Application

1. Molybdenum heat shields are used in high-temperature and

sapphire growth furnaces due to their ability to withstand high

temperatures and corrosion.

2. Heat parts have high density, precise measurement, and smooth

surfaces, making them excellent for improving crystal pulling.

3. Heaters are made of Molybdenum, Tungsten, and its alloy

materials, which is widely used in high-temperature furnace, vacuum

furnace of ceramic, metallurgy, electronics, glass, and refractory

materials industries.